Glass processing

We care about every millimeter. Precision in production creates harmony and the individual components follow each other nicely.

Over a period of 25 years of operation, we have made custom glass for thousands of satisfied customers. In addition, we processed more than 15,760 m edges of glass, laminated more than 12,000 m2 of glass, graphically printed more than 9,670 m2 of glass.

Part of our comprehensive service with professional installation are special solutions made of glass and all-glass systems. At present, we focus mainly on design stairs, doors and glass partitions in an industrial style, where we use the full potential of our company.

We care about every millimeter. Precision in production creates harmony and the individual components follow each other nicely.

Over a period of 25 years of operation, we have made custom glass for thousands of satisfied customers. In addition, we processed more than 15,760 m edges of glass, laminated more than 12,000 m2 of glass, graphically printed more than 9,670 m2 of glass.

Part of our comprehensive service with professional installation are special solutions made of glass and all-glass systems. At present, we focus mainly on design stairs, doors and glass partitions in an industrial style, where we use the full potential of our company.

Custom glass

Flat glass processing

| Machine type: | horizontal CNC automat |

| Cutting shapes: | rectangular and atypical |

| Maximum standard size: | 3210x2550 mm |

| Cutting thickness: | 3-19mm |

| Maximum glass thickness: | 30mm |

| Maximum glass size: | 3300mm |

| Machine type: | three-axis CNC automatic milling machine |

| Machining accuracy: | 0,5 mm |

| Maximum size: | 2800x1400, other dimensions on request |

| Maximum thickness: | 19 mm depending on the selected tool type |

| Materials for production: | in digital format .dxf or .dwg, or a template (we will supply its required parameters on request) |

- Drilling standard hole diameters (4; 5; 6; 8; 10; 12; 14; 16; 18; 20; 22; 24; 26; 28; 30; 32; 34; 36; 38; 40; 42 mm)

- Countersinking holes below 45 degrees. angle / li>

- Production of atypical and visually machined holes:

- minimum ground diameter 20 mm

- minimum diameter polished 30 mm

- Milling of holes and cutouts of various shapes and sizes with min. with a radius of 8 mm with a ground edge and 15 mm with a polished edge

| Features: | high-strength, clear joints, fast curing under UV light |

| Bonded materials: | glass - glass, glass - metal / td> |

| Use for gluing: | glass furniture, glass hinges, glass trophies, decorative items, information boards |

| Tensile and market strength: | 26N / mm2, depending on the materials to be bonded and the type of adhesive used |

| Heat resistance: | -40 ° C to +120 ° C, the strength decreases from 100 ° C |

| Varnish type: | NANO technology ClearShield |

| Varnish color: | clear |

| Varnish properties: reduces surface contamination, reduces the capture of impurities and minerals from water (limescale), easier cleaning of glass, reduces the formation of dew, protection of sandblasted glass surfaces | |

| Use: tiling glass in shower enclosures, walls and doors for shower enclosures, sandblasted glass surfaces, bathroom mirrors, conservatory glazing, facades | |

| Colored NANO varnishes: | for coloring sample sandblasts |

Flat glass decoration

| Machine type: | vertical sanding machine |

| Minimum size: | 3210 x 2250 mm, other dimensions on request |

| Maximum size: | 80 x 80 mm |

| Maximum glass thickness: | 3200 x 2550 mm |

| Materials for sample sandblasting: | in digital format .cdr, .eps, .ai, .dxf or for less demanding patterns, an image or .pdf is sufficient |

| The use: | interior partitions, glass doors, kitchen glass screen, ... |

| Color: | according to shades RAL, NCS, PANTONE other shades by agreement |

| Method of application: | spraying |

| Technical color information: | moisture resistance, chemical resistance, solvent resistance, scratch resistance, surface adhesion, abrasion resistance, salt resistance, QUV test, flexural resistance, spray hardness, sunlight resistance |

| Use of painted glass: | wall coverings, kitchen worktops, furniture fillings, furniture coverings, bathtub linings, shower enclosure walls |

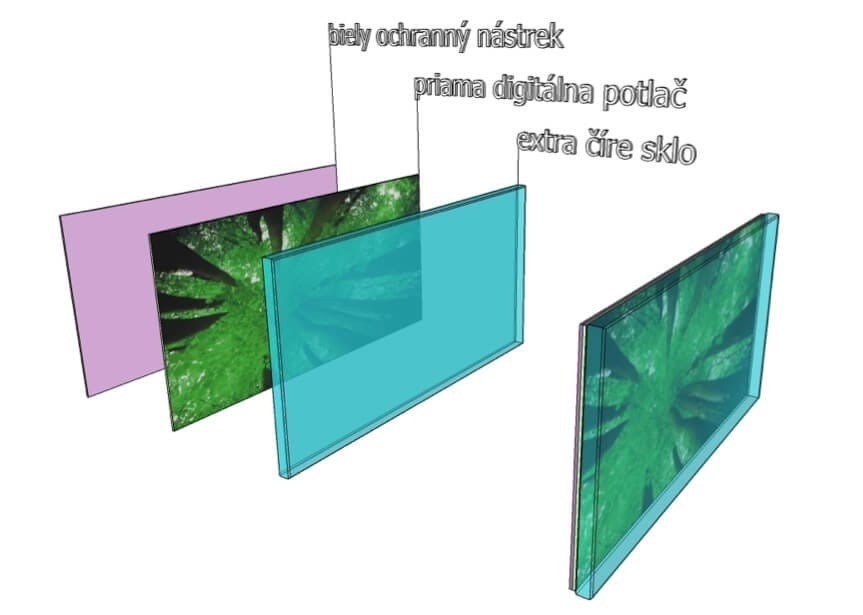

| Maximum size: | 1600 x 3200 mm |

| Maximum glass thickness: | 80 mm |

| Document formats for printing: | .jpeg, .pdf, .tif as agreed with the graphic designer |

| Minimum image resolution: | 150 dpi at the actual size of the final print image |

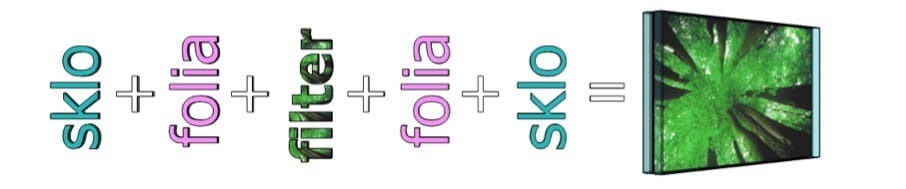

| Maximum size: | 3200 x 1700 mm (depending on the thickness and shape of the glass) |

| Insert materials: | colored foils, textiles, dried natural materials, wood veneer, wallpaper |

| The use: | doors, kitchen screens, tiling glass, walk-in glass, railings, decorative items |

| Sandblasting type: | model |

| Minimum size: | 80 x 80 mm |

| Maximum size: | 3200 x 2550 mm |

| Maximum glass thickness: | 40 mm |

| Maximum sandblasting depth: | depending on the thickness of the glass, standard 3-4 mm |

| Glass type: | soft glass - float |

| The use: | plaques, awards and other design elements |

Production of safety glass

| Minimum size: | 150 x 300 mm |

| Maximum size: | 3210 x 2250 mm, other dimensions on request |

| Aspect ratio: | 1:20 |

| Thickness: | 4 – 19 mm |

| Strength: | tempered glass is 4 - 5 times stronger than basic glass Float, when testing a sheet of glass 4 mm thick shows a resistance of 120 N / mm2 |

| Usage: shower enclosures, wall coverings, glass doors, glass partitions, furniture glass, glass on facades, loggia glazing |

| Minimum size: | 250 x 100 mm |

| Maximum size: | 6000 x 3210 mm |

| Thickness: | 4 – 19 mm |

| The use: | for special constructions (in use in laminated glass for awnings, roofs, walkable glass) |

| Glass thickness: | 6 – 50 mm |

| Maximum size: | 3000 x 1700 mm (depending on the thickness and shape of the glass) |

| Minimum size: | 100 x 150 mm |

| Maximum unit weight: | 600 kg |

| The use: | railings, partitions, facades, awnings, roofs, stairs, pedestrian glass, load-bearing structures, decorative glass |

| By laminating glass it is possible to achieve: | protection against injury, protection against falling, protection against burglary, bulletproof glass, protection of property against UV radiation, glass resistant to explosion and explosion. |

| The use: | for mirrors and glass in frames (eg doors, built-in cabinets) and mirrors hung on walls, which could injure people or damage property if broken |

| Features: | after breaking such glass with the protective foil, the glass remains together |

At your request, we will perform a Hubble test to detect nickel sulfite. After testing the glass, the risk of spontaneous breakage is reduced to 0.025%. When consulting with our technicians, you will receive all the necessary information for the HST test, which is described in detail in the Slovak standard STN EN 14179-1 and 2.

| Minimum glass size for the Hubble process: | diagonal> 300 mm |

| Maximum glass size for the Hubble process: | 2100 x 4000 mm |

| Minimum radius: | ground> 8 mm, polished> 12.5 mm |

| Other processing options after the Hubble process: | full-area and sample sandblasting, varnishing, lamination, gluing with graphic foils |

| The use: | cladding glass on facades, load-bearing glass and all glass in which it is necessary to minimize the risk of spontaneous explosion |

We also offer

| Individual glass packaging: | into wooden packaging, plastic carob covers, foam and cardboard protectors |

| Standard glass packaging: | the possibility of renting an A-stand or the purchase of a disposable wooden stand |

| Special glass packaging: | packaging of glass products and oversized or extremely heavy glass |

| Own transport: |

|

| Shipping service: | individually depending on the size and weight of the glass |

Testing of glasses for special applications within our capabilities.

Maximum counseling time: as needed